1/89 Stanley Rd, Ingleburn NSW 2565

Locally owned and operated since 2010

Mon - Thu : 6:00 AM - 4:00 PM | Fri : 6:00 AM - 1:00 PM

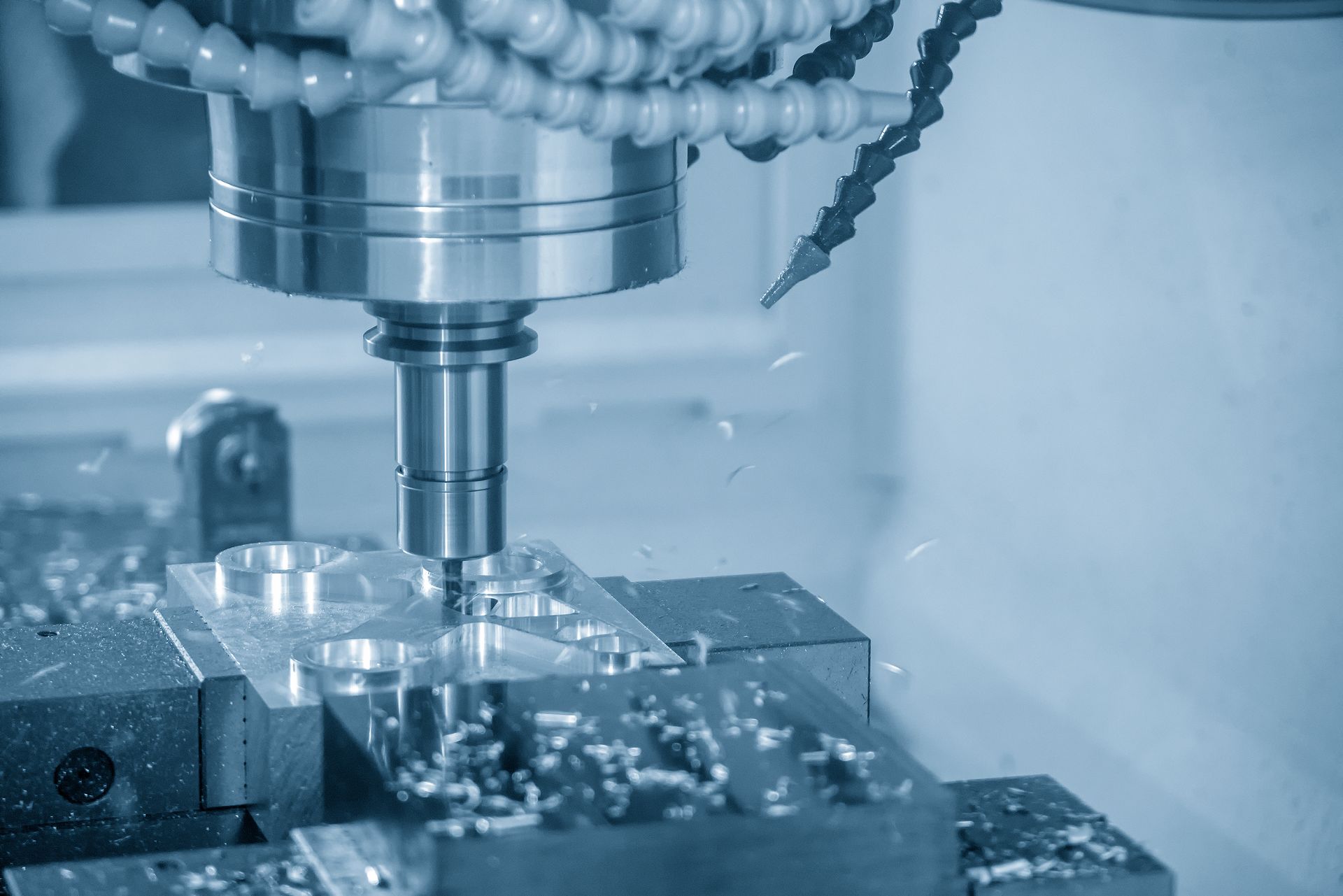

CNC Milling

Get high-quality custom milled parts at the most competitive prices. Our CNC milling services are available for rapid prototyping and mass production.

High Precision CNC Milling Service

CNC Precision Machining specialises in efficient CNC milling services, crafting custom prototypes and precision components for various industries, including automotive, aerospace, molds, and intricate machinery. Our advanced software and equipment ensure high accuracy, meeting deadlines without compromising quality. With competitive pricing, we're a cost-effective choice for outsourcing milling needs.

In CNC machining, the decision between turning and milling depends on factors like part geometry, material properties, production volume, and machining complexity. Get in touch to discuss your project.

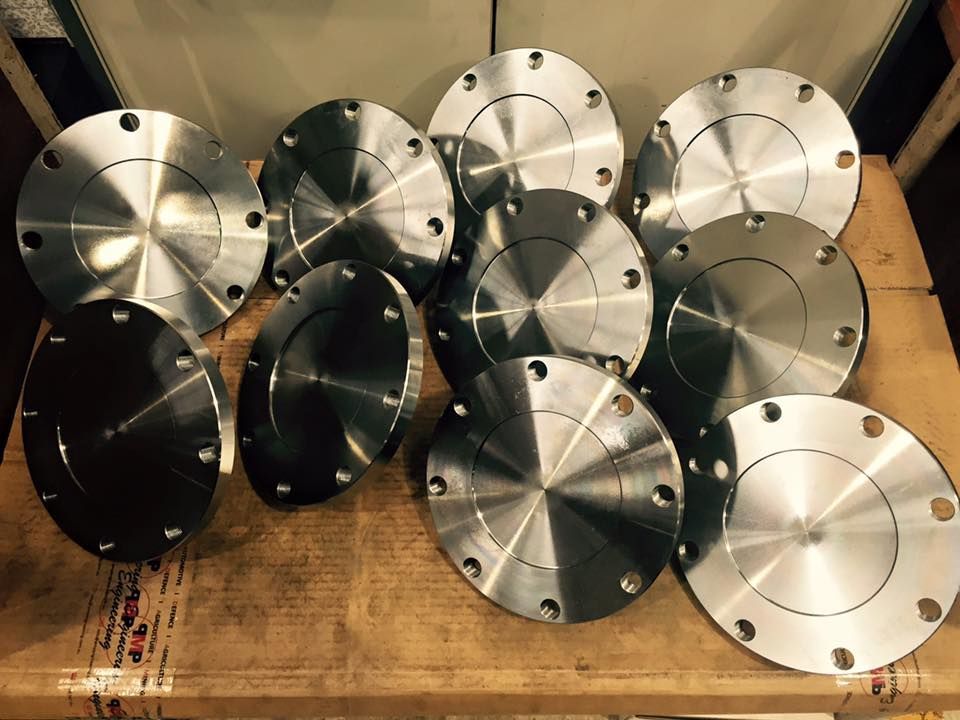

Components Crafted through CNC Milling

- Fittings: Milled fittings that seamlessly connect two or more components.

- Enclosures and Housings: Custom-milled enclosures safeguard internal components in electrical devices and other products.

- Brackets: Precision-milled brackets featuring custom threads and holes, often more intricate than their sheet metal counterparts.

- Gears: CNC milling yields both straight and spiral gears for various mechanical devices.

- Mold Tooling: Rapid prototyping of molded parts facilitated by milled tooling, typically crafted from steel or aluminum.

- Engine Parts: Automotive engineers leverage CNC milling for the production of engine blocks and other critical components.

- Medical Devices: CNC mills play a crucial role in crafting implants, surgical instruments, and various medical devices.

- Water Pumps: Multi-axis mills excel in creating dependable impellers for hydraulic equipment.

- Forming Punches: CNC mills contribute to the manufacturing process by crafting equipment such as forming punches essential for sheet metal fabrication.

Materials We Work On

Metal

- Aluminium

- Steel

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

Plastic

- ABS

- Polycarbonate (PC)

- Nylon

- Polypropylene (PP)

- POM

- PTFE (Teflon)

- PMMA (Acrylic)

- Polyethylene (PE)

- PEEK

- Bakelite

- FR4

- Rubber

If the specific material you are seeking is not listed, we encourage you to reach out to us as we might be able to work on it.

Our CNC Milling Capabilities

Horizontal Machining

- Horizontal Machining

- Single and Twin Pallet

- 15,000 RPM spindle

- Through coolant

- 4 axis (full B)

- Prototype through to production machining

Vertical Machining

- Single Pallet

- 4 Axis

- 10,000 RPM

- Prototype through to production machining

Advantages of CNC Milling Over Conventional Machining

-

Precision Enhancement

CNC milling offers enhanced precision in manufacturing. This allows for the quick removal of large amounts of metal as well as engineering-grade plastic resins. It also ensures intricate details are faithfully reproduced.

-

Efficiency and Versatility

In addition to increased efficiency through automated processes, CNC milling enables the production of complex shapes. This means it provides a versatile solution for crafting components with intricate geometries.

-

Consistent Accuracy and Swift Prototyping

The repeatable accuracy of CNC milling not only ensures a high level of reliability in replication, but also contributes to the swift prototyping of designs, facilitating rapid idea validation and refinement.

-

Labour Savings

Labour savings are realised with advanced processes like CNC milling, where automated workflows reduce the need for extensive manual labour and streamline the manufacturing process.

-

Material Versatility

Material versatility is a key advantage of CNC milling, as it accommodates a wide range of substances from metals to plastics. This allows for the machining of diverse materials with precision and consistency.

-

Consistency Upgrade

The consistency upgrade provided by CNC milling results in standardised output, meeting exacting standards and specifications for each manufactured component.

-

Speedier Production

Speedier production is achieved through CNC milling, which accelerates the manufacturing process, meeting the demands of businesses requiring efficient and timely production.

Our Proficiency is Your Strategic Advantage

Please don't hesitate to reach out with any enquiries or questions you may have regarding our services. Our team is here to provide you with the information you need to explore how we can assist in the development of your new product or process.

With over 20 years of experience and state-of-the-art machinery, we lead in providing CNC consumables to industries like Mining, Rail, Medical, Defence and Automotive. Conveniently located in Ingleburn, NSW 2565, our CNC machining center ensures high-quality technical support, products and service. Committed to quality management with ISO 9001:2000 standards, CNC Precision Machining values our customers, suppliers, and employees as one family, striving for continuous excellence in manufacturing.

Quicklinks

Find Us

1/89 Stanley Rd, Ingleburn NSW 2565